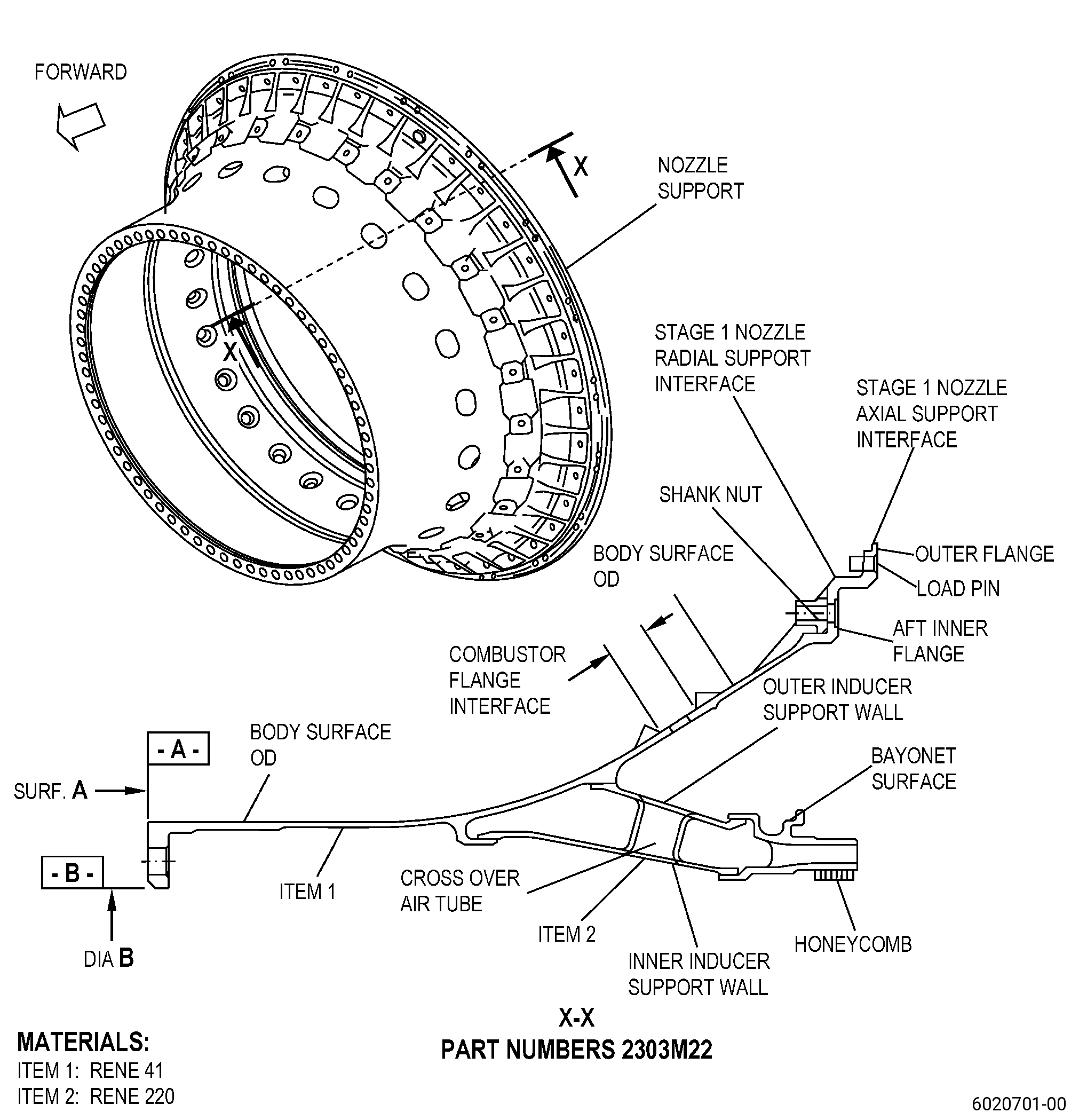

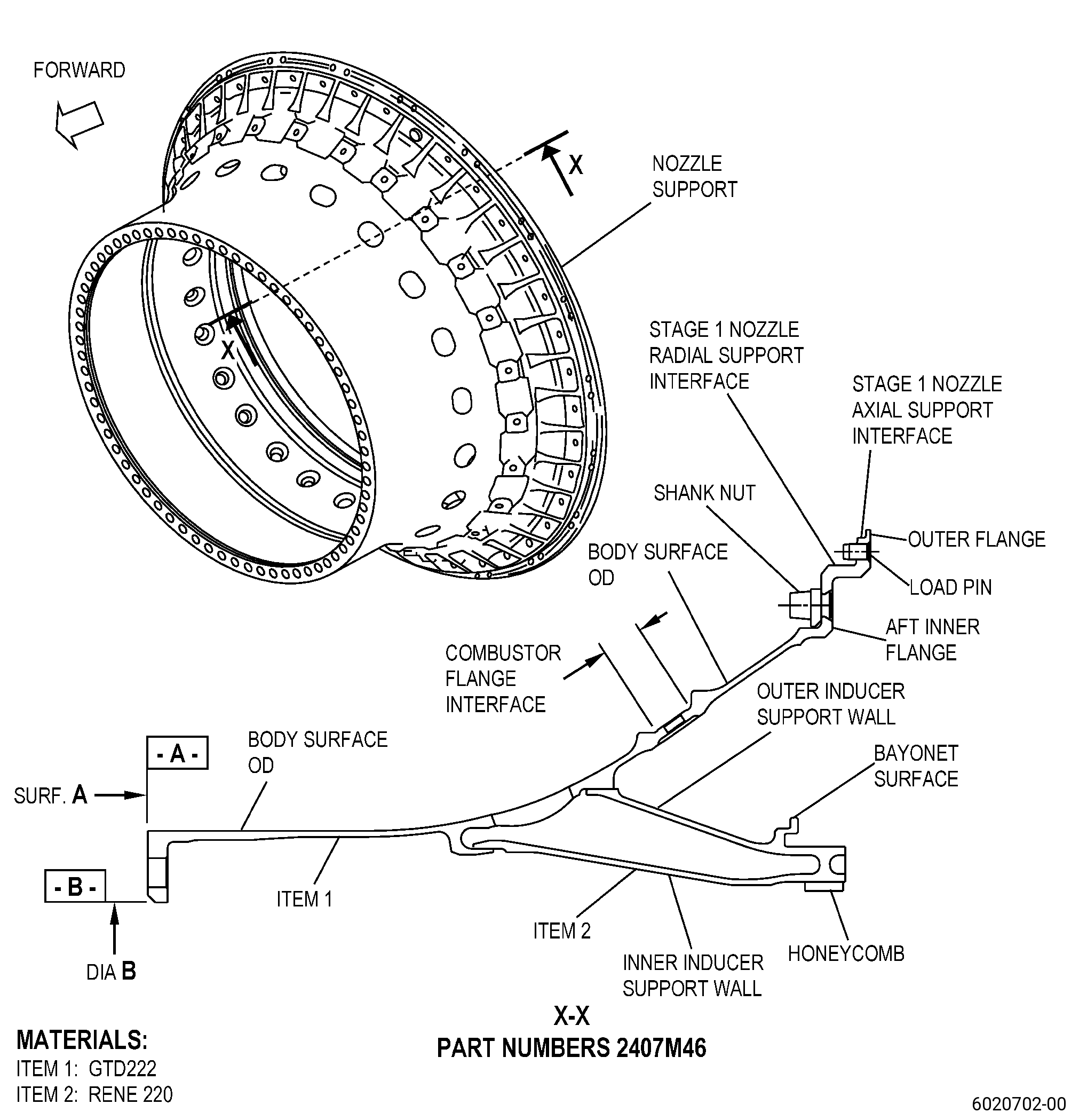

| GENX-1B CLEANING,INSPECTION,AND REPAIR MANUAL | Dated: 11/18/2020 |

| CIR 72-51-01 , REPAIR 012 | ||

| HIGH PRESSURE TURBINE STAGE 1 NOZZLE SUPPORT - REPAIR - WELD LINEAR INDICATION REPAIR OF THE INDUCER OUTER SUPPORT WALL, INNER SUPPORT WALL, AND CROSS OVER TUBES | ||