| GENX-1B CLEANING,INSPECTION,AND REPAIR MANUAL | Dated: 02/28/2025 |

| CIR 72-32-01 , REPAIR 003 | ||

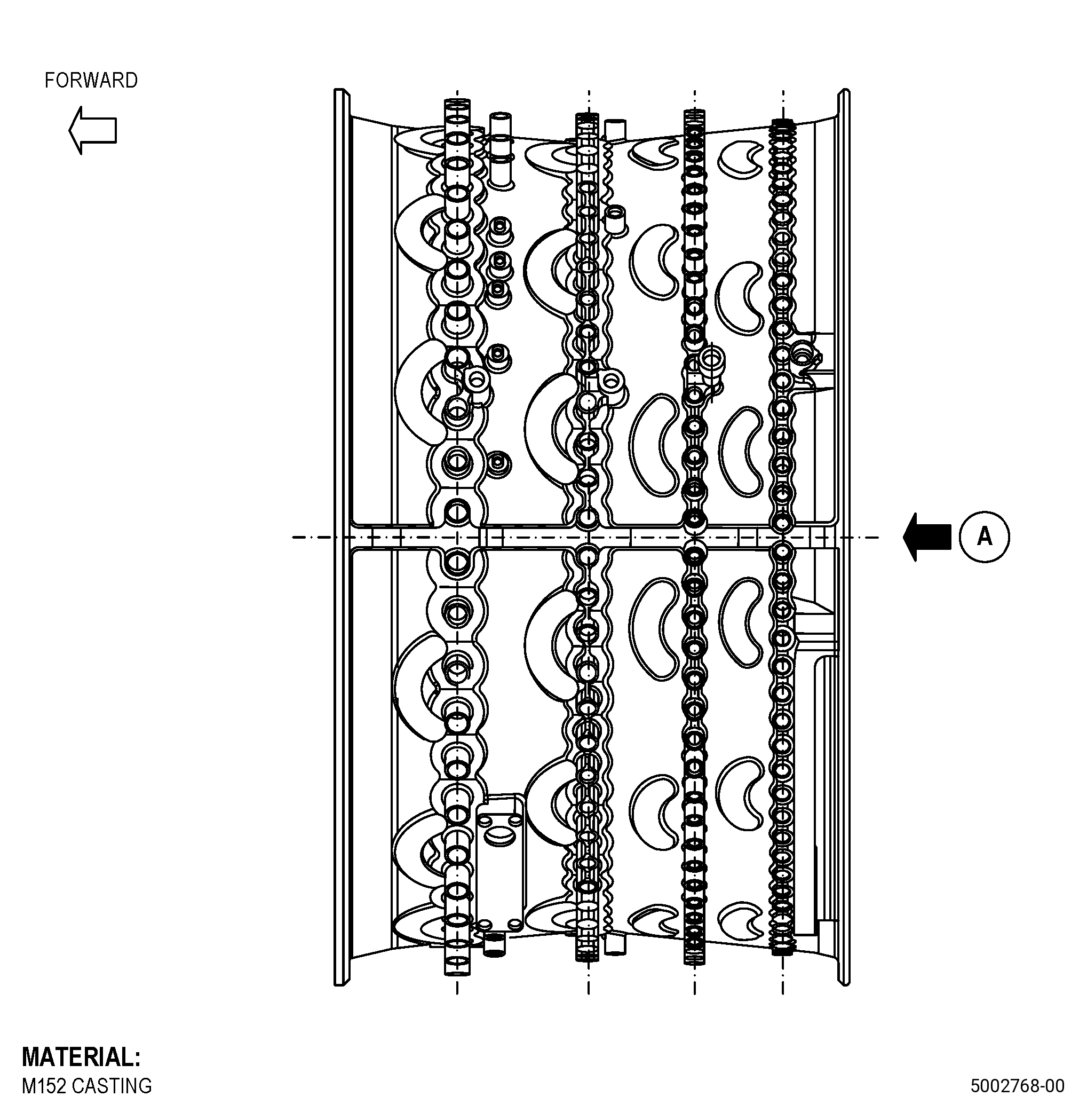

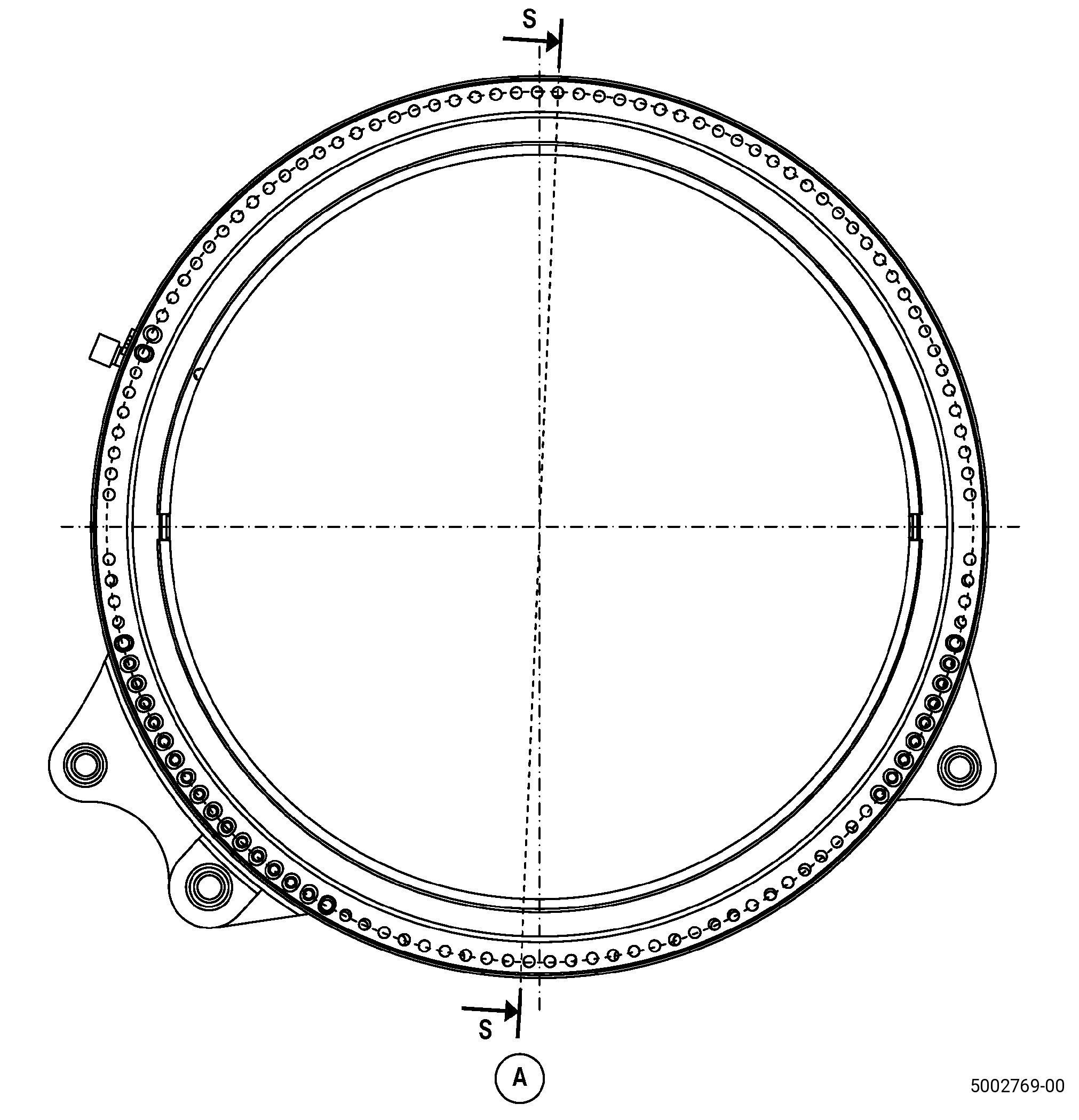

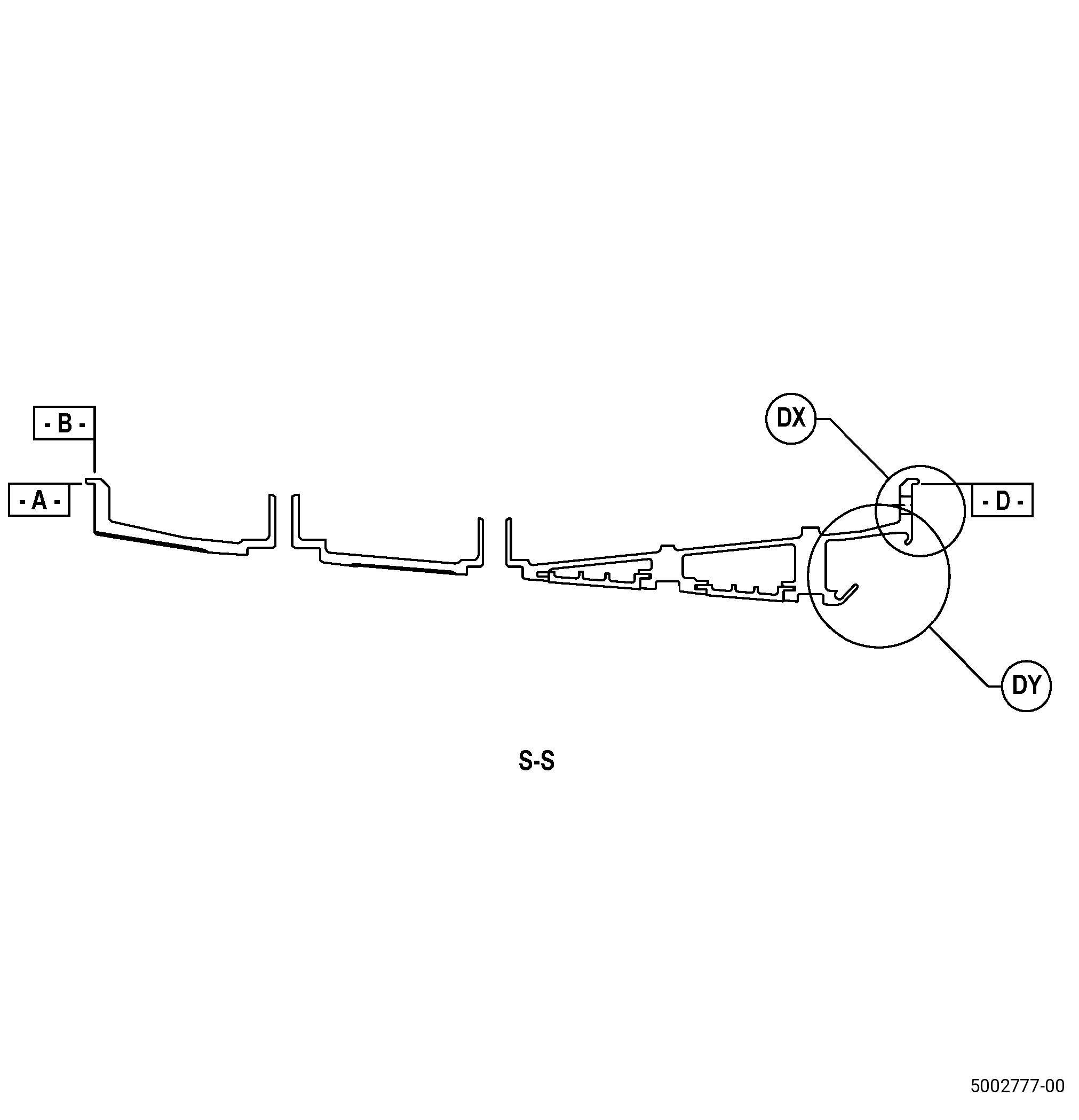

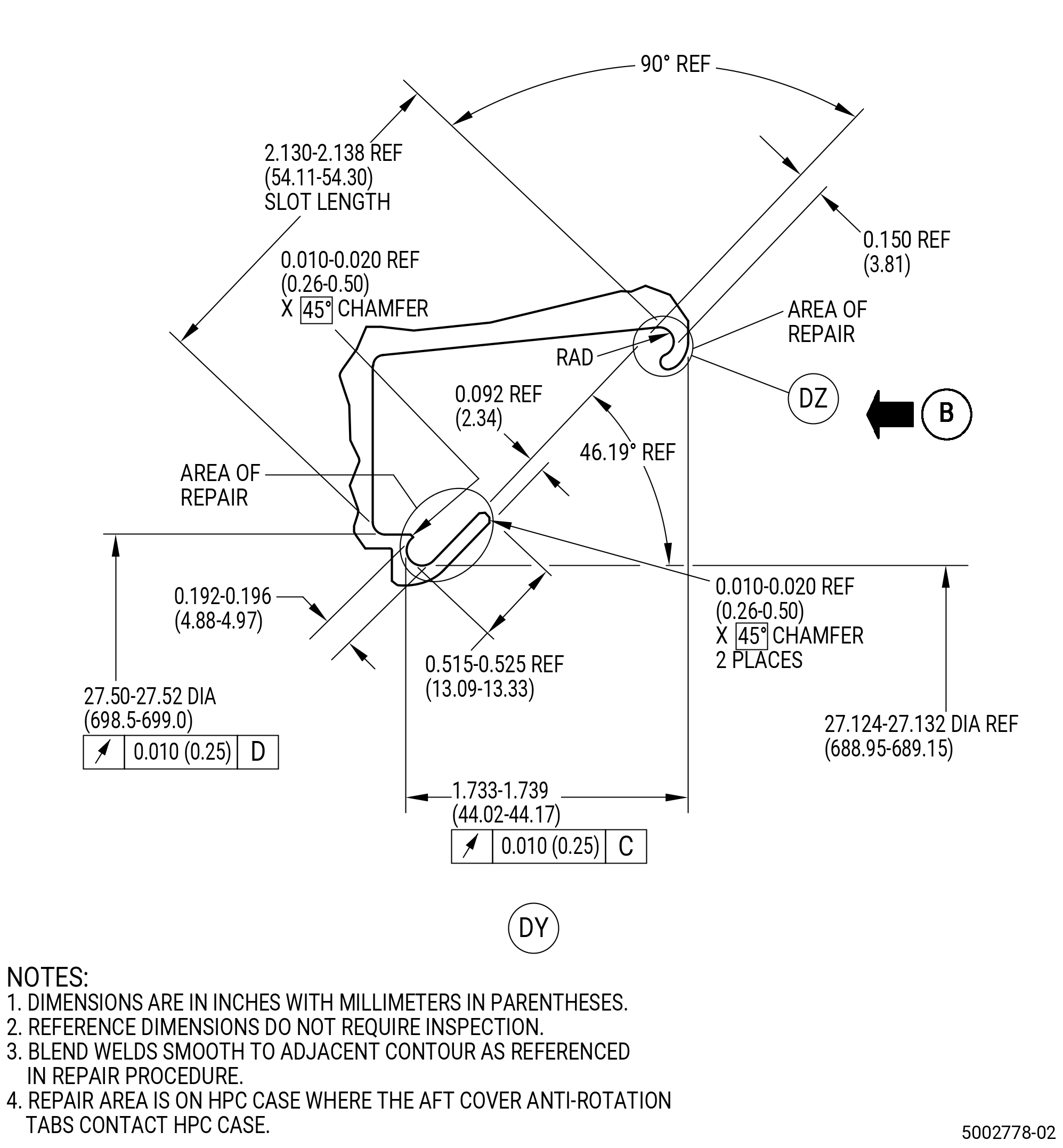

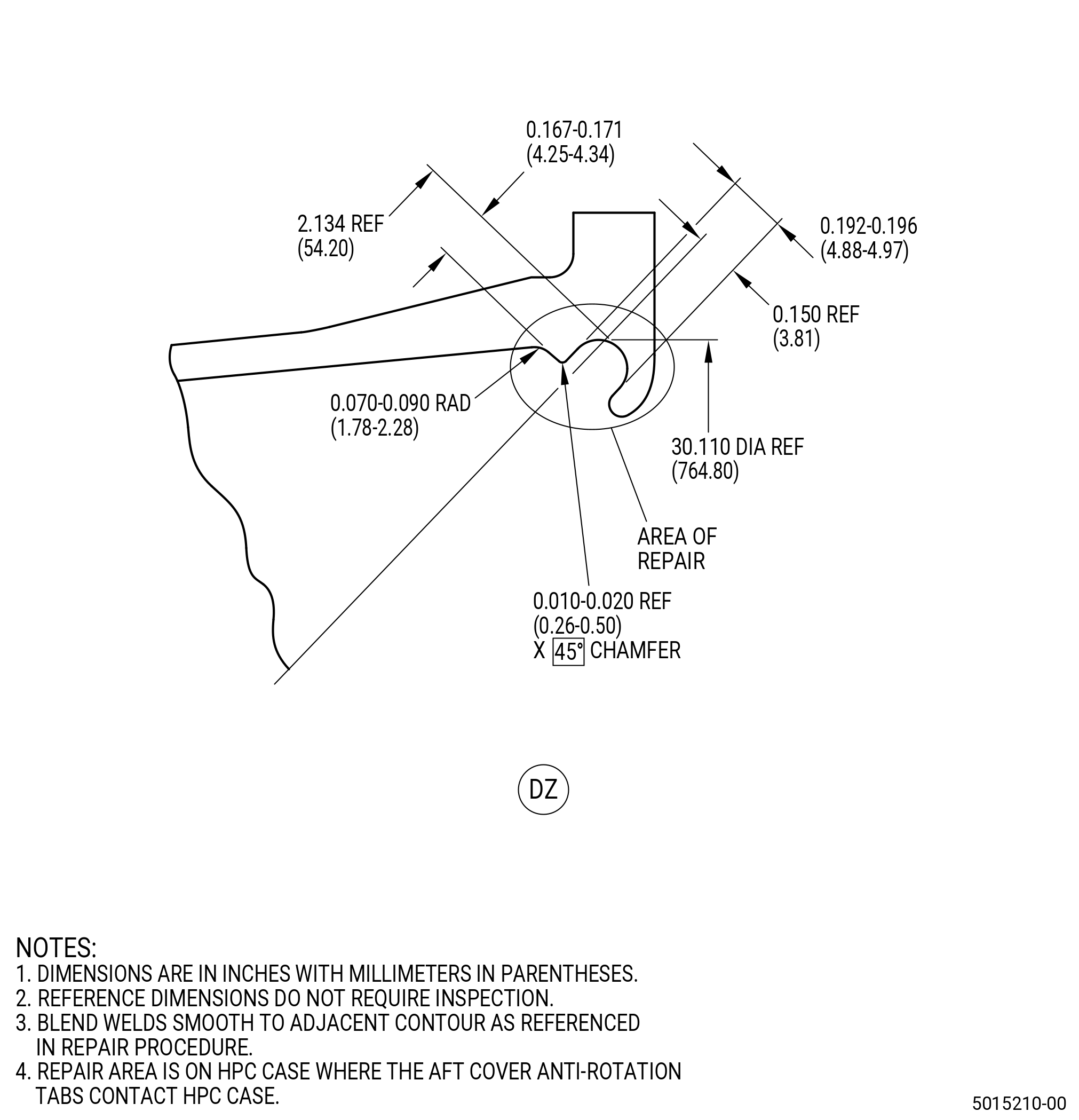

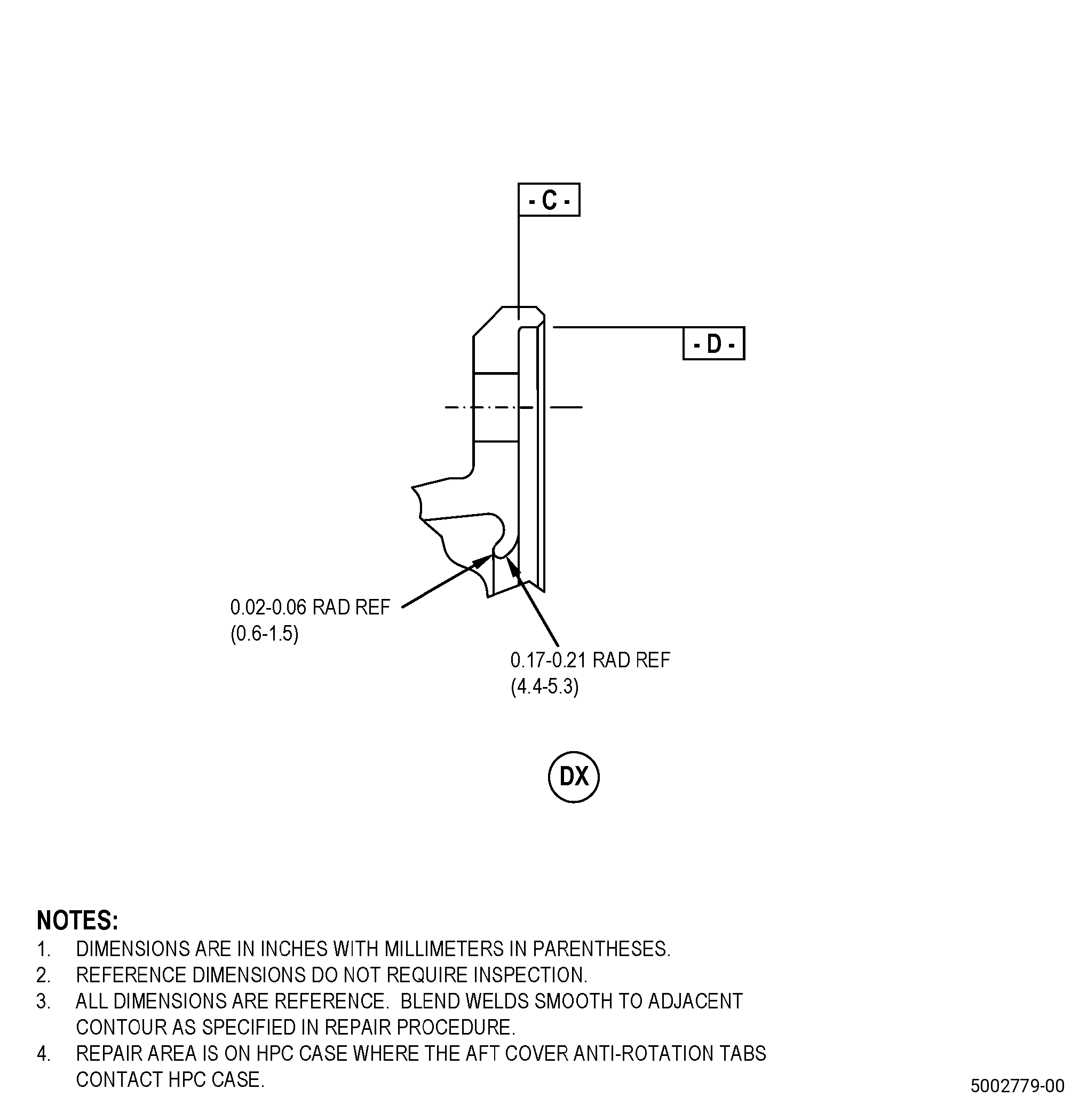

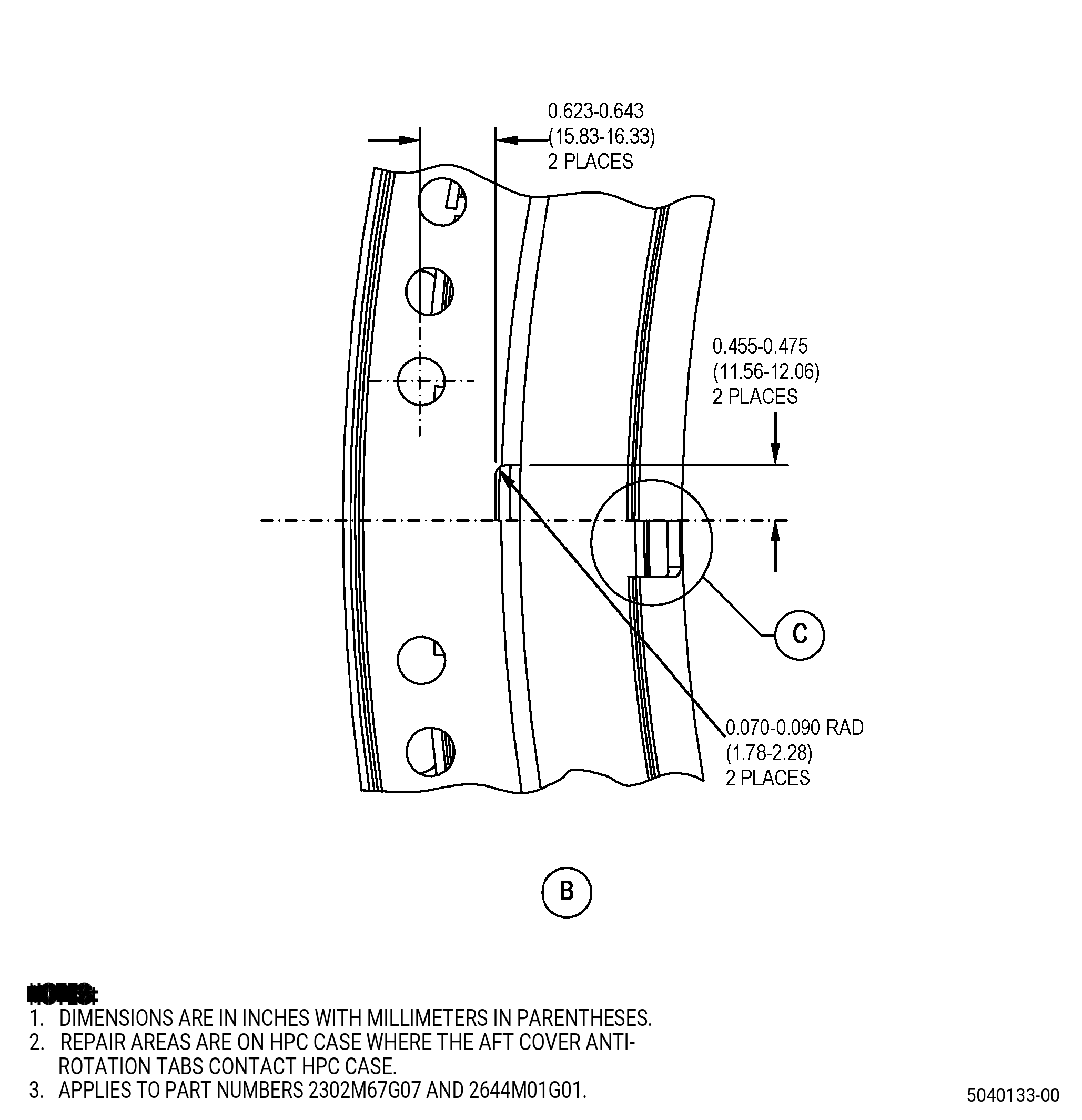

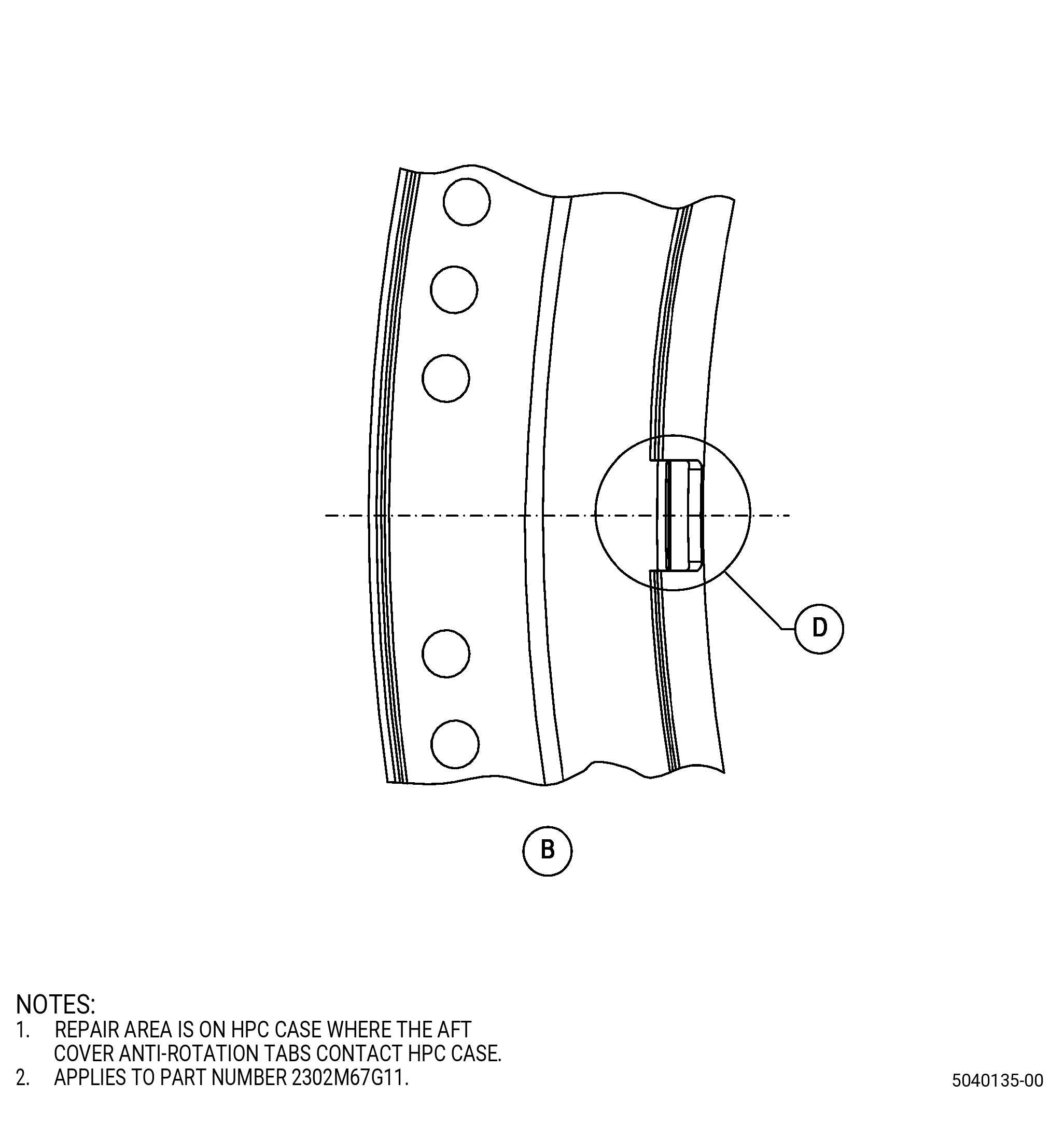

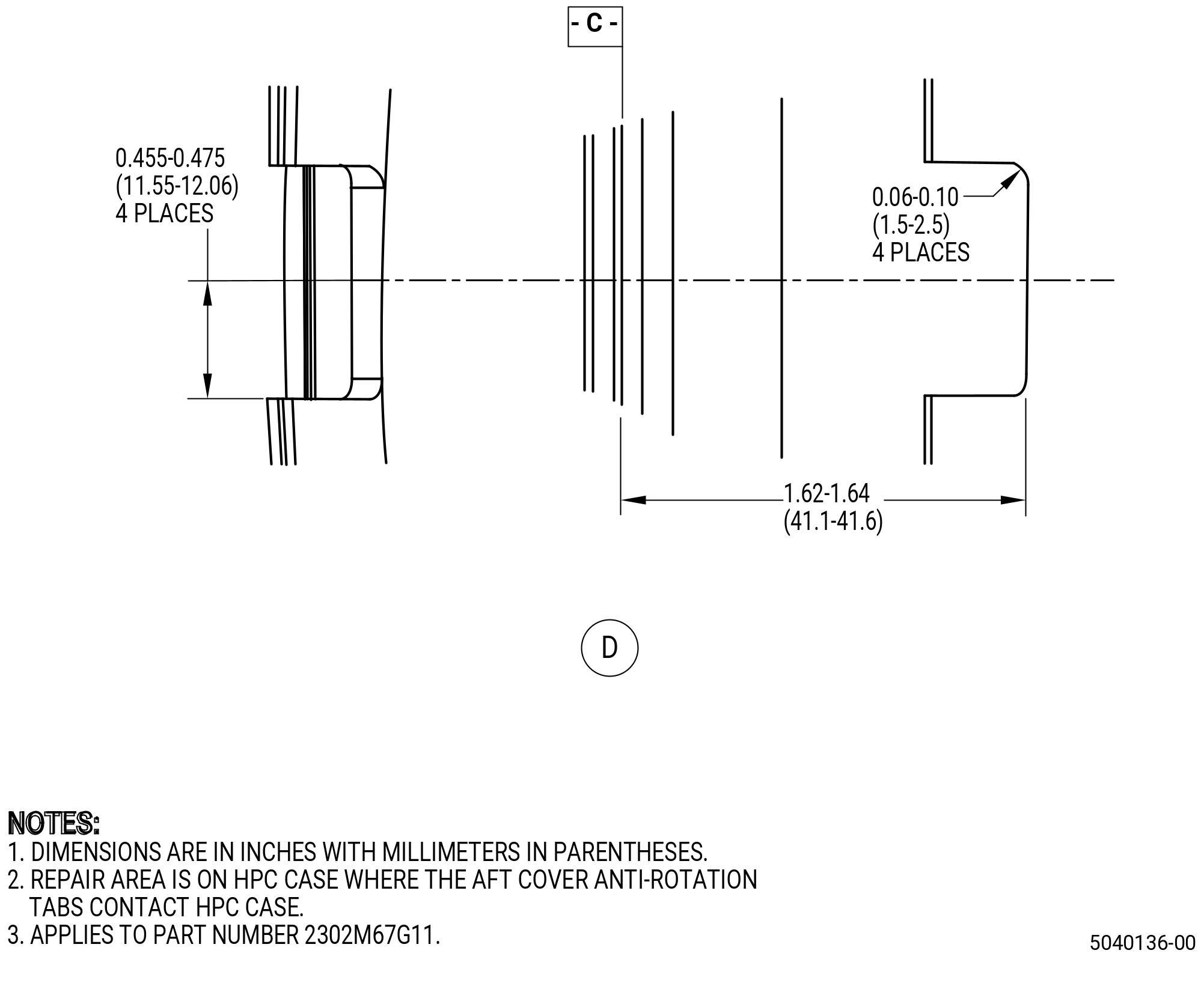

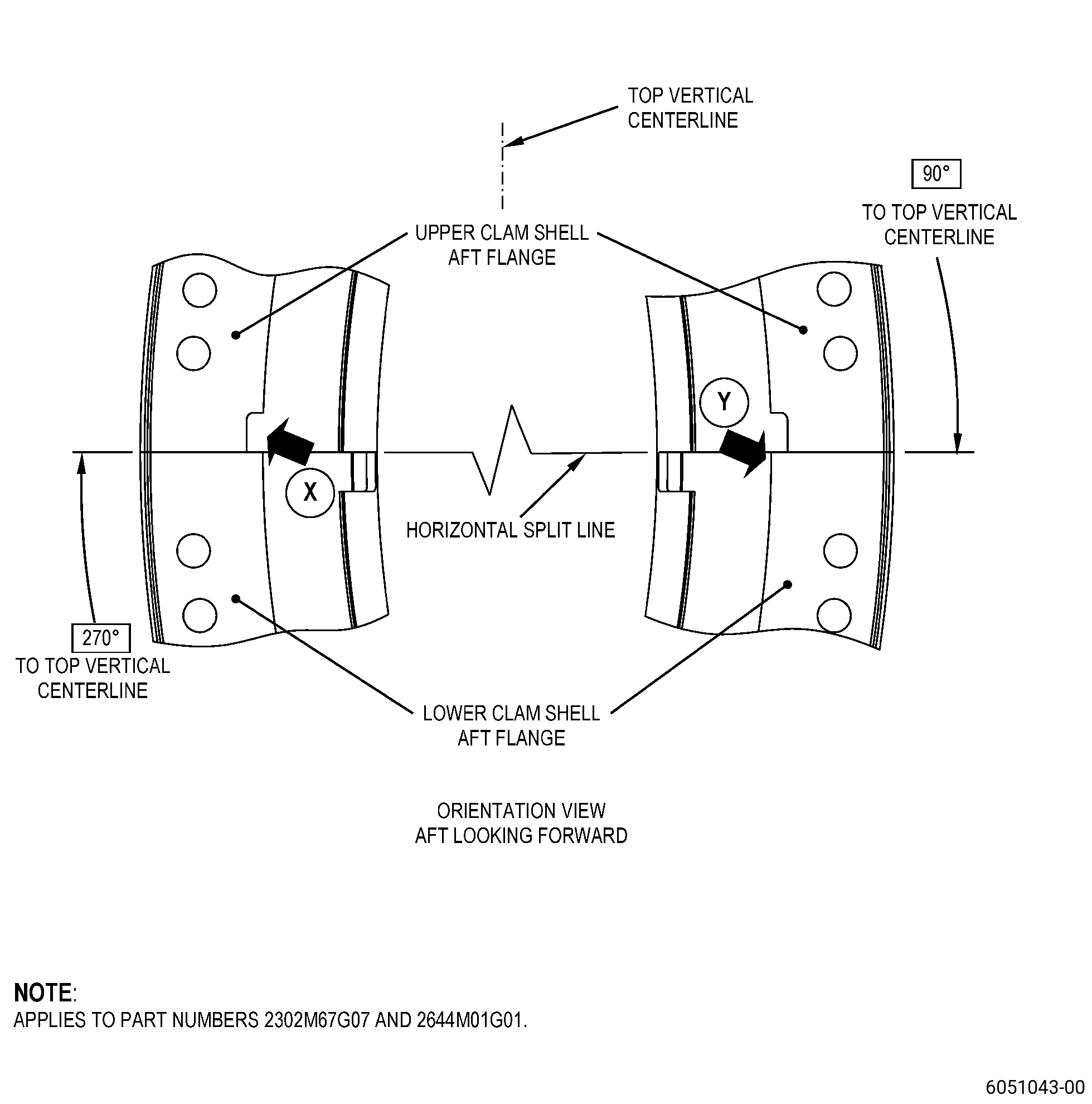

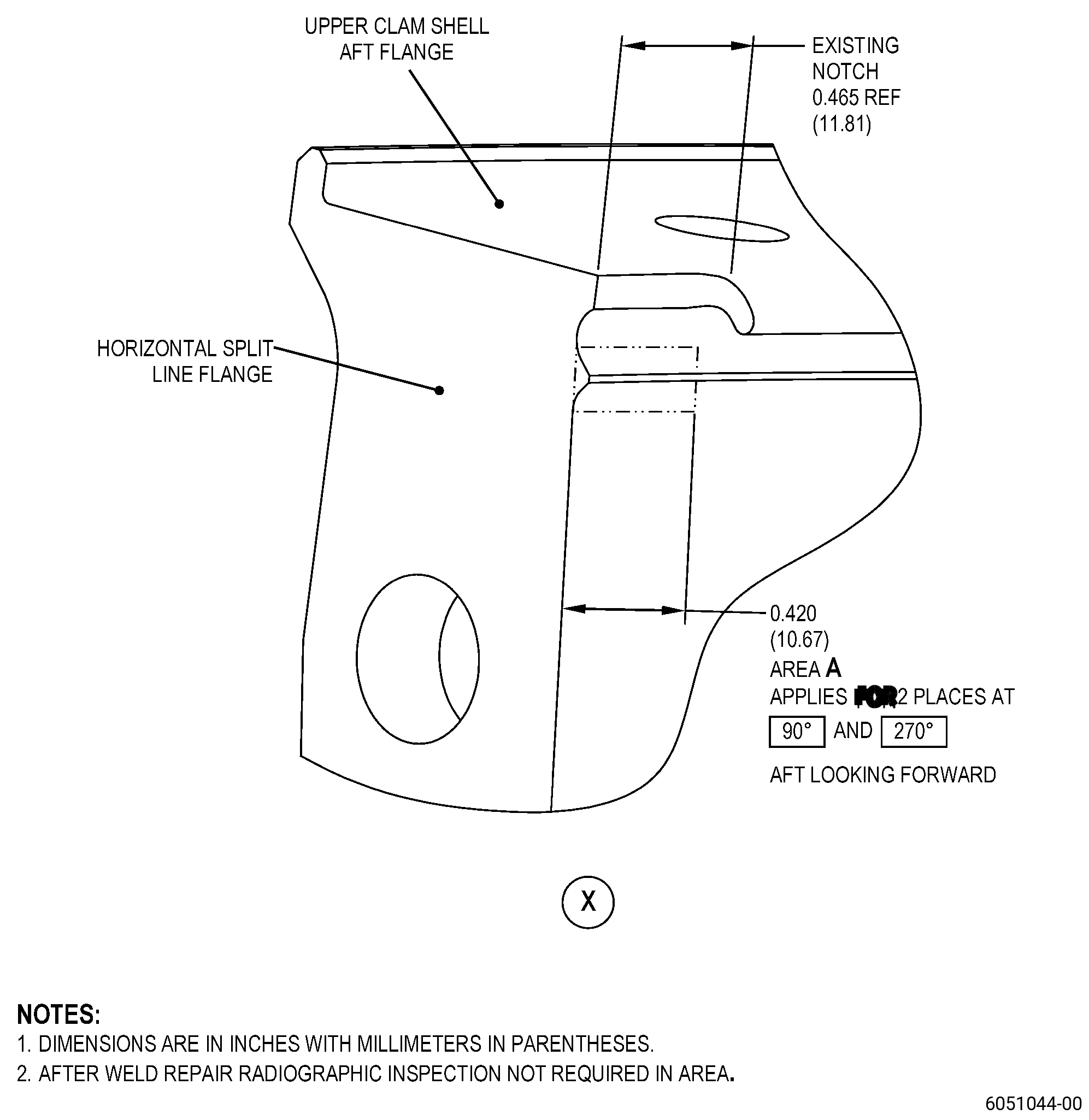

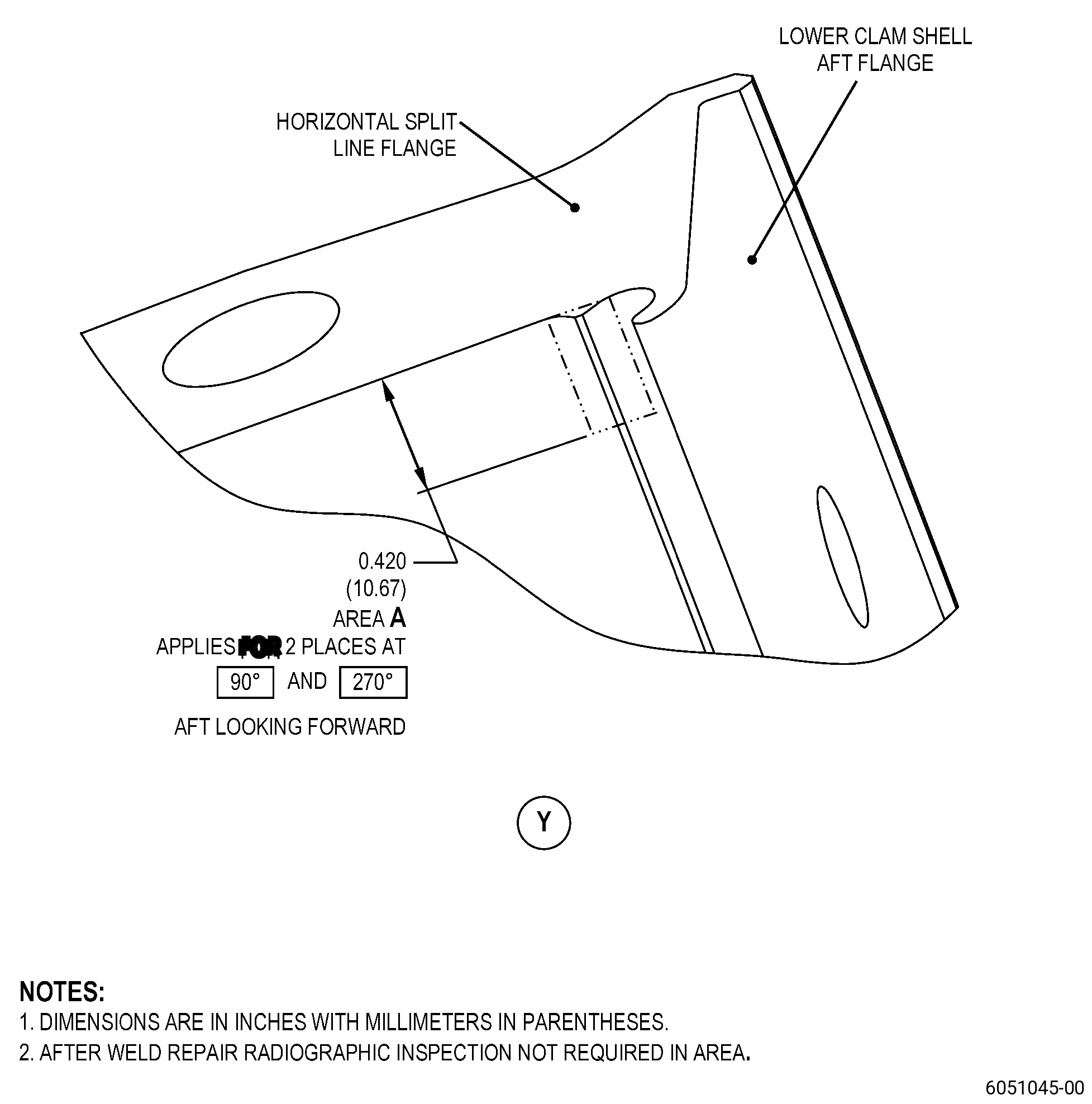

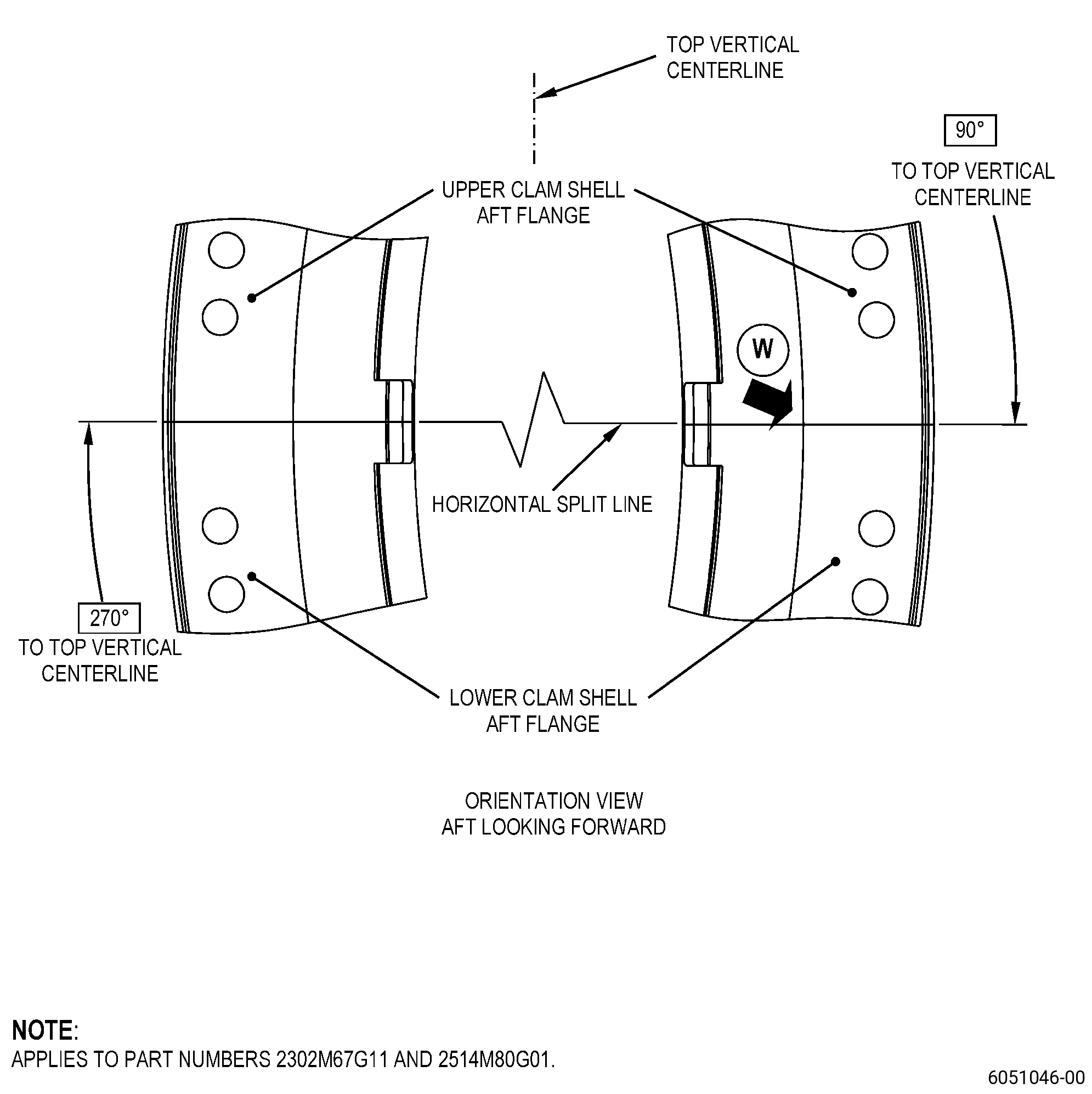

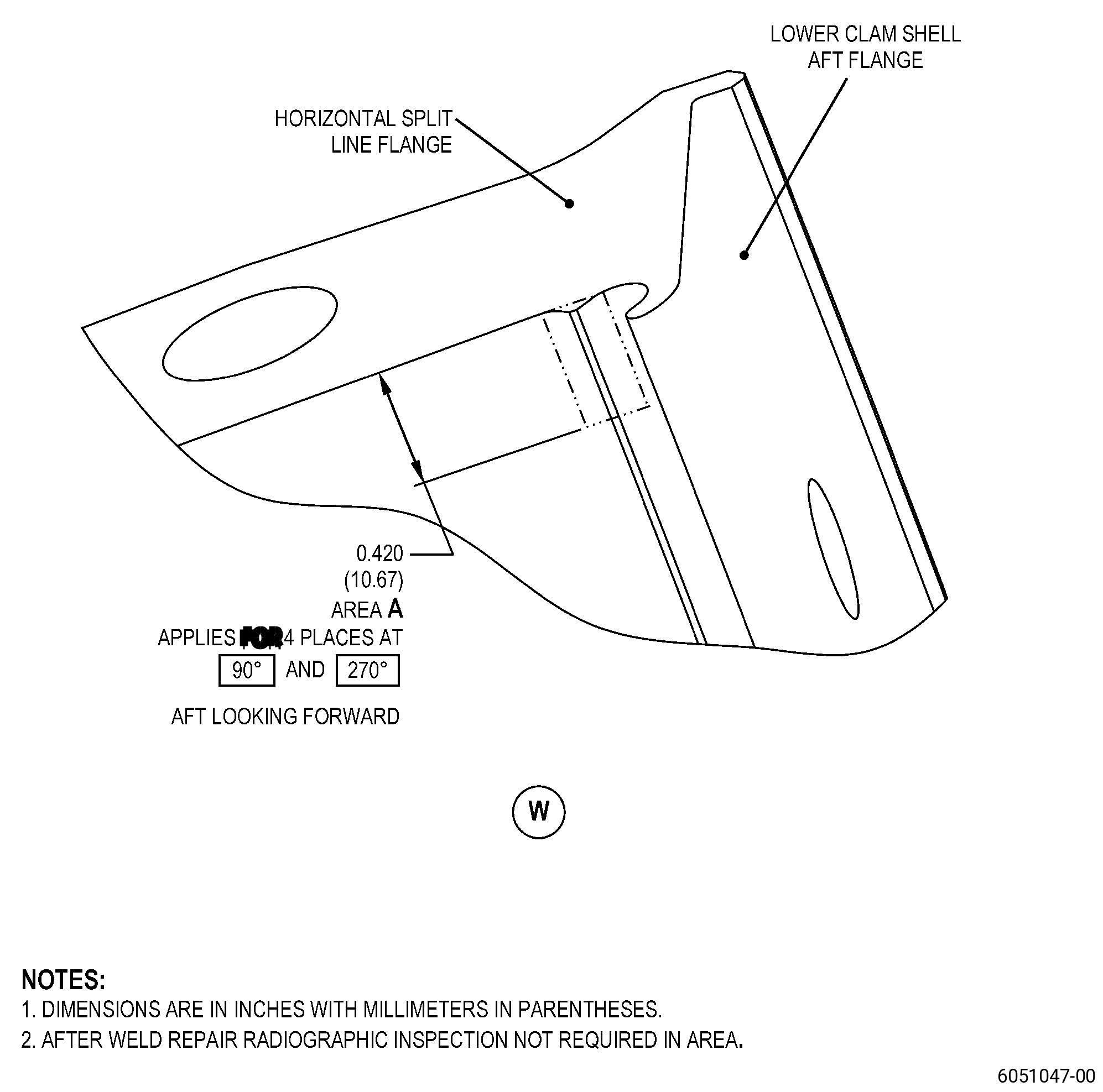

| HIGH PRESSURE COMPRESSOR STATOR FORWARD CASE ASSEMBLY - REPAIR - WELD REPAIR OF THE VANE SECTOR TONGUE (DEFLECTOR RAIL) WEAR AT THE AFT COVERS ON THE FORWARD CASE | ||